What are Scaffold Mesh and Scaffolding Mesh?

Scaffold mesh and scaffolding mesh are strong protective materials designed specifically for safety on construction sites. They are made of woven or knitted synthetic fibers that can endure tough outdoor conditions while still being sturdy throughout long projects.

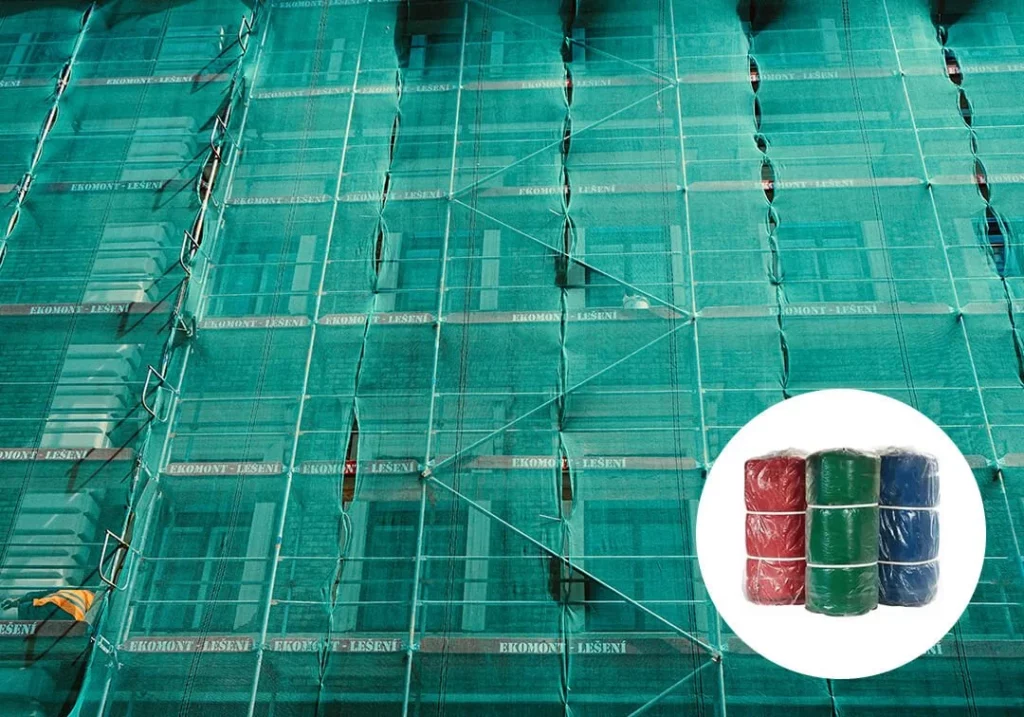

The construction industry depends on these materials as crucial safety barriers. Contractors use them to cover scaffolding structures and create safe spaces around work areas. The main uses of scaffold mesh include:

- Debris containment – stopping tools, materials, and construction waste from falling down

- Dust control – reducing airborne particles that spread beyond the work area

- Privacy screening – blocking public view of ongoing work

- Wind protection – creating barriers that lessen wind impact on workers and materials

Physical Specifications

Different types of construction netting have standard sizes that make it easy to install them on various scaffolding systems. The mesh usually comes in rolls that are 1.83 meters wide and 50 meters long, but custom sizes can be made for specific project needs.

The color options serve both practical and visual purposes:

- Black mesh – provides maximum privacy and UV protection

- Blue mesh – offers high visibility for safety compliance

- Green mesh – blends with environmental surroundings in residential areas

Structural Features

The material has reinforced eyelets spaced evenly along the edges. These metal-reinforced holes allow secure attachment to scaffolding poles using zip ties, bungee cords, or specialized clips. The eyelet spacing usually ranges from 250mm to 500mm, providing flexible mounting choices.

The way the mesh is woven determines its protective abilities. Tighter weaves offer better debris containment and dust control, while more open patterns allow for better airflow and visibility. Manufacturers measure mesh density using a shade factor percentage, indicating how much light and air the material blocks.

Weather resistance is an important part of the design. Quality scaffolding mesh can withstand:

- UV damage from prolonged sun exposure

- Moisture absorption that leads to mold growth

- Extreme temperatures causing material brittleness

- Wind loads that put stress on attachment points

These protective materials must meet local safety standards, ensuring they fulfill minimum strength requirements for construction sites.

Are Scaffold Mesh and Scaffolding Mesh the Same Material?

Do these terms refer to identical products? Yes, scaffold mesh and scaffolding mesh are essentially the same material, with the terms used interchangeably throughout the construction industry. The terminology comparison reveals no meaningful distinction between the two names—both describe the same high-strength protective netting designed for construction site safety.

Why does the industry use both terms? The dual terminology stems from linguistic preference rather than material differences. Construction professionals, suppliers, and manufacturers switch between “scaffold mesh” and “scaffolding mesh” depending on regional dialects, company naming conventions, or simply personal preference. A contractor in one region might request “scaffold mesh” while another orders “scaffolding mesh,” yet both receive identical products from the same supplier.

What material similarities exist between them? The material similarities are complete because they represent the same product category:

- Identical construction methods: Both utilize woven or knitted high-density polyethylene (HDPE) or similar synthetic fibers

- Matching specifications: Standard dimensions of 1.83 m × 50 m rolls apply to both terms

- Same physical properties: UV stabilization, weather resistance, and tensile strength remain consistent regardless of terminology

- Equal safety standards: Compliance with construction safety regulations applies uniformly to products under either name

How do design and function compare? The design and function between scaffold mesh and scaffolding mesh show zero variation. Both feature reinforced eyelets spaced at regular intervals for secure attachment to scaffolding frames. The mesh density, shade factors, and debris containment capabilities remain identical. Whether labeled as scaffold mesh or scaffolding mesh, the product serves the same protective purposes: debris containment, dust control, wind reduction, and privacy screening on construction sites.

How Do These Meshes Enhance Safety on Construction Sites?

These meshes create multiple protective barriers that address the most common hazards found on elevated work platforms. The primary function centers on debris containment, where the tightly woven material catches falling tools, building materials, and construction waste before they reach ground level. This barrier system protects pedestrians walking below and prevents damage to vehicles or property in the surrounding area.

1. Dust Control

Dust control represents another critical safety function during demolition, cutting, or grinding operations. The mesh fabric acts as a filter that significantly reduces airborne particles from spreading beyond the work zone. Construction sites in urban environments particularly benefit from this feature, as it minimizes respiratory hazards for workers and reduces complaints from neighboring buildings or businesses.

2. Wind Protection

The wind protection capabilities serve a dual purpose on exposed sites. The mesh reduces wind speed passing through the scaffolding structure, which prevents lightweight materials from becoming projectiles during gusty conditions. Workers experience improved comfort levels when shielded from constant wind exposure, allowing them to maintain focus on precision tasks without environmental distractions. The reduced wind load also contributes to overall scaffold stability.

3. Privacy Screening

Privacy screening adds value beyond pure safety metrics. The mesh conceals ongoing work from public view, which matters for renovation projects on occupied buildings or sites handling sensitive materials. This visual barrier also prevents unauthorized individuals from observing site layouts or security measures.

The mesh density determines how effectively each function performs. Higher density options provide superior dust filtration and privacy but may reduce natural light penetration. Lower density variants maintain better visibility while still offering adequate debris containment and privacy screening. The material’s UV-resistant properties ensure these protective qualities remain consistent throughout extended project timelines, even under harsh weather exposure.

What Factors Affect the Protection Offered by Scaffold and Scaffolding Mesh?

Several factors influence how effective scaffolding and its accompanying mesh are in providing protection on construction sites. Understanding these factors can help you choose the right materials and ensure optimal safety measures. Here are the key elements that affect the protection offered by scaffold and scaffolding mesh:

1. Mesh Density

Mesh density stands as the primary determinant of protection effectiveness. The shade factor—expressed as a percentage—indicates how much light and debris the mesh blocks. Higher density meshes (70-90% shade factor) provide superior debris containment and dust control but reduce visibility for workers. Lower density options (30-50%) allow better airflow and visibility while still offering basic protection against larger falling objects.

2. Material Strength

Material strength directly impacts how well the mesh performs under stress. Construction-grade meshes manufactured from high-density polyethylene (HDPE) or polypropylene resist tearing when struck by debris or subjected to strong winds. UV-stabilized materials prevent degradation from prolonged sun exposure, maintaining structural integrity throughout extended projects. Meshes without proper UV treatment deteriorate within months, creating dangerous gaps that compromise site safety.

Other Resources : What do the numbers on plastics really mean?

3. Installation Quality

Installation quality determines whether the mesh functions as designed. Properly secured mesh with reinforced eyelets attached at regular intervals creates a taut barrier that catches debris effectively. Loose or improperly fastened mesh flaps in the wind, creating gaps where materials can escape. The spacing between attachment points should follow manufacturer specifications—typically every 500mm along vertical and horizontal edges.

4. Safety Compliance

Safety compliance ensures the mesh meets industry standards for construction site protection. Certified meshes undergo testing for tensile strength, fire resistance, and debris containment capabilities. Regulatory bodies in different regions mandate specific performance criteria that meshes must satisfy before use on commercial construction sites.

5. Weather Conditions

Weather conditions at the project location influence mesh selection. Coastal sites require corrosion-resistant materials and higher wind-load ratings. Urban environments with heavy dust production benefit from denser weaves that trap fine particles. The mesh’s ability to handle rain without sagging or collecting water pockets affects long-term performance and safety.

Which Offers Better Protection: Scaffold Mesh or Scaffolding Mesh?

Do these two terms represent different protection levels? No—scaffold mesh and scaffolding mesh deliver identical safety performance because they describe the same product category. The protection comparison scaffold vs scaffolding mesh reveals no meaningful distinction in their protective capabilities.

Both terms refer to high-strength woven or knitted materials manufactured to meet identical safety standards and construction requirements. The safety performance evaluation depends entirely on the product specifications rather than the terminology used to describe it.

Key factors determining protection remain consistent regardless of naming:

- Material composition (typically HDPE or similar polymers)

- Mesh density and shade factor percentage

- UV stabilization and weather resistance

- Tensile strength ratings

- Compliance with regional safety regulations

The choice between products labeled as “scaffold mesh” versus “scaffolding mesh” should focus on verifiable specifications rather than terminology. A mesh marketed as “scaffold mesh” with 80% shade factor provides identical protection to a “scaffolding mesh” with the same specifications.

Manufacturers often use these terms interchangeably in product catalogs and technical documentation. The protective value stems from measurable characteristics—density, material quality, and proper installation—not from which term appears on the packaging. Site managers should evaluate mesh products based on their certified performance metrics rather than linguistic variations in product names. Check out more about LVL Construction Products for Stronger, More Consistent Structural Builds.

How to Choose the Right Mesh for Your Construction Project

Choosing the right scaffold mesh for your construction project involves considering various factors specific to your site and project requirements. Here are some key factors to keep in mind:

1. Assess Environmental Exposure

The environmental conditions of your construction site play a crucial role in determining the type of mesh you need. Consider the following:

- Coastal Sites: If your project is located near the coast, you’ll need meshes that offer superior UV resistance and corrosion-proof eyelets to withstand the harsh marine environment.

- Urban Projects: For projects in urban areas, dust containment capabilities may be a top priority to minimize disruption to surrounding buildings and streets.

2. Consider Debris Type

The type of debris generated during construction will influence your choice of mesh. Different types of work produce different kinds of waste:

- Heavy Construction Work: If you’re involved in heavy tasks such as working with concrete, bricks, or metal fragments, opt for higher-density mesh with reinforced edges to ensure durability and safety.

- Renovation Projects: On the other hand, if your project involves lighter debris like drywall dust or wood shavings, standard-density options should suffice without compromising safety.

3. Evaluate Wind Exposure

Wind exposure at your site is another critical factor to consider when selecting mesh. The permeability of the mesh will affect how wind interacts with scaffolding structures:

- High-Rise Projects or Exposed Locations: For tall buildings or areas prone to strong winds, choose meshes with calculated shade factors between 50-70%. This will help reduce wind load on scaffolding while still containing debris.

- Completely Enclosed Meshes: Be cautious with completely enclosed meshes as they may create dangerous wind resistance that compromises scaffold stability.

4. Factor in Project Duration

The length of time your project will be ongoing can impact the materials you choose:

- Temporary Installations: If you only need scaffolding for a few weeks, lighter-weight meshes should be sufficient.

- Long-Term Projects: However, if your project is expected to last several months or longer, invest in heavy-duty materials that can withstand continuous exposure to weather elements.

5. Verify Regulatory Compliance

Different regions have specific safety regulations that must be followed during construction:

- Local Safety Standards: Ensure that any scaffolding mesh you select meets these local standards—particularly regarding fire resistance ratings and load-bearing specifications.

- Specific Density Requirements: Some jurisdictions may also require certain mesh densities based on building heights or proximity to public areas.

6. Consider Your Budget

When making decisions about materials, it’s essential not only look at initial costs but also long-term value:

- Premium Meshes vs Lower-Grade Replacements: While premium meshes with reinforced borders and UV-stabilized materials may come with higher upfront costs, they can reduce replacement frequency and potential safety incidents over time.

- Total Project Timeline Calculation: Calculate the total duration of your project—this will help determine whether investing in higher-quality mesh provides better value compared to purchasing multiple lower-grade replacements.

7. Account for Construction Site Requirements

Finally, don’t forget about any specific requirements related directly to visibility needs:

- Public Viewing or Inspection Access: If there are areas where public viewing or inspection access is necessary (such as building facades), semi-transparent meshes might be required.

- Privacy-Sensitive Sites: Conversely, if privacy is a concern (like residential properties), opaque options that completely obscure the work area would be more appropriate.

By carefully considering these factors—environmental exposure, debris type, wind exposure, project duration regulatory compliance budget considerations ,and construction site requirements—you’ll be able make an informed decision when choosing the right scaffold mesh for your construction project .

Conclusion

Does it really matter whether we call it scaffold mesh or scaffolding mesh? The truth is, both terms refer to the same protective material used on construction sites.

When it comes to ensuring safety on a construction site, the names we use are not as important as the following factors:

- Choosing high-quality materials: This is crucial when sourcing mesh for any project. Look for woven or knitted fabrics that are strong and meet industry safety standards.

- Using proper installation techniques: Even the best mesh won’t provide adequate protection if it’s not installed correctly. Make sure to securely fasten the mesh using reinforced eyelets, maintain appropriate tension levels, and regularly inspect it throughout the project.

- Prioritizing site-specific needs: Different construction sites have different requirements. Ensure that you comply with relevant safety regulations and choose the right mesh density based on your specific conditions.

Instead of getting caught up in the debate over terminology, site managers should focus their efforts on these practical measures:

- Material strength and weather resistance capabilities

- Compliance with relevant safety regulations

- Correct mesh density for specific site conditions

- Professional installation by trained personnel

- Routine maintenance and damage assessment

The discussion about scaffold mesh versus scaffolding mesh ultimately distracts us from what really matters in protecting construction sites. It’s time to shift our attention towards selecting durable materials, implementing proper installation protocols, and maintaining the integrity of our mesh. These actions will provide the necessary protection for construction teams, regardless of which term is used on the product label.