What Is Laminated Veneer Lumber (LVL) and How Is It Made?

Laminated veneer lumber is an engineered wood product created by bonding multiple thin layers of timber veneers together with high-strength adhesives under controlled conditions. Unlike traditional solid timber that comes directly from a single log, LVL transforms smaller pieces of wood into a high-performance structural material through precise manufacturing processes.

The engineered nature of LVL sets it apart from conventional lumber. Each veneer layer measures approximately 3mm thick and runs parallel to the length of the finished product. This consistent grain orientation throughout the entire piece eliminates the natural weaknesses found in solid timber, such as knots, splits, and varying grain patterns that compromise structural integrity.

The Manufacturing Journey from Log to Structural Component

The production of laminated veneer lumber begins with carefully selected logs from sustainably managed plantations. These logs typically come from fast-growing softwood species like pine, spruce, or Douglas fir, though hardwood veneers can also be used for specific applications requiring enhanced properties.

The manufacturing process follows several critical stages:

- Log Preparation and Peeling: Selected logs arrive at the processing facility where they undergo debarking and cutting to optimal lengths. The logs then move to rotary peeling machines that work like giant pencil sharpeners, unwinding continuous sheets of veneer as the log rotates against a sharp blade. This peeling method maximizes yield from each log while maintaining consistent veneer thickness.

- Drying to Precise Moisture Content: Fresh-cut veneers contain high moisture levels that would compromise adhesive bonding and final product stability. The veneers pass through large kiln dryers where controlled heat reduces moisture content to approximately 8-12%. This kiln-drying process is essential for engineered wood production, as it prevents future shrinkage, warping, or dimensional changes in the finished LVL product.

- Quality Grading and Defect Removal: After drying, each veneer sheet undergoes inspection. Automated scanning systems and trained operators identify defects such as large knots, splits, or areas of decay. These imperfections are cut out and replaced with sound wood patches, ensuring every section of veneer meets structural standards

Why Are LVL Construction Products Stronger Than Traditional Timber?

LVL construction products are stronger than traditional solid timber because of their engineered layered structure and uniform grain orientation. This design makes LVL significantly stronger than conventional wood.

The Science Behind LVL Strength

The strength of LVL comes from two main factors: its layered structure and uniform grain orientation.

Layered Structure

The layered structure of LVL creates a composite material where each veneer layer reinforces the others. Traditional timber contains natural defects like knots, splits, and varying grain patterns that reduce its structural capacity. LVL eliminates these weaknesses by using thin veneers where defects can be identified and removed or strategically placed to minimize impact on overall strength.

Uniform Grain Orientation

Uniform grain orientation ensures that wood fibers run parallel to the length of the beam in every layer. This alignment maximizes tensile and compressive strength along the primary load-bearing axis. Solid timber often contains cross-grain patterns and irregular growth rings that create stress concentrations under load, leading to premature failure.

The Role of Adhesive Bonding

The adhesive bonding between layers distributes stress evenly across the entire cross-section. When load is applied, the glue lines transfer forces between veneers, preventing individual layers from separating or buckling. This integrated behavior allows LVL to function as a single, homogeneous structural element rather than multiple independent wood pieces.

Quantifying LVL’s Load-Bearing Capacity

LVL demonstrates load-bearing capacity that rivals engineered materials traditionally considered superior to wood:

- Bending strength: LVL typically achieves bending stress values of 48-55 MPa, compared to 30-40 MPa for standard construction-grade solid timber

- Modulus of elasticity: LVL reaches 13,000-14,000 MPa, indicating greater stiffness and resistance to deflection than conventional lumber at 8,000-11,000 MPa

- Compression parallel to grain: LVL handles 40-45 MPa, exceeding solid timber’s 25-35 MPa capacity

These mechanical properties position LVL as a viable alternative to steel and concrete in many applications.

How Does LVL Ensure Consistency and Reliability in Structural Builds?

LVL delivers consistent performance through its engineered manufacturing process that eliminates the natural defects found in traditional timber. Every piece of LVL maintains identical mechanical properties because the production method systematically removes or redistributes wood irregularities that would otherwise create weak points in the structure.

The Elimination of Natural Defects

Traditional solid timber contains knots, splits, checks, and grain irregularities that create unpredictable weak spots throughout each piece. These natural characteristics mean that two pieces of timber cut from the same tree can have dramatically different load-bearing capacities. LVL construction removes this uncertainty entirely.

The veneer peeling process identifies and removes defective sections before assembly. Knots that would compromise a solid timber beam get cut away during veneer preparation. The thin veneer layers allow manufacturers to inspect each sheet for quality, rejecting any sections with significant flaws. This quality control step happens before the bonding process, ensuring only sound wood material enters the final product.

When veneers are laminated together, any minor imperfections that remain get dispersed throughout the cross-section rather than concentrated in one location. A small knot in one veneer layer becomes insignificant when surrounded by dozens of clear wood layers above and below it. This distribution of minor defects prevents the stress concentrations that cause traditional timber to fail unexpectedly.

Uniform Mechanical Properties Across Every Piece

Structural reliability stems from LVL’s predictable behavior under load. Engineers can specify exact load capacities knowing that every LVL beam with the same dimensions will perform identically. This uniformity contrasts sharply with solid timber, where each piece must be individually graded and may still contain hidden weaknesses.

The grain orientation in LVL remains parallel throughout the entire length and depth of each piece. Solid timber often contains cross-grain sections, spiral grain patterns, or reaction wood that creates internal stresses. These grain irregularities cause unpredictable deflection and can lead to sudden failure when loads exceed localized weak points.

LVL’s controlled moisture content during manufacturing adds another layer of consistency. Every veneer gets kiln-dried to a specific moisture level before bonding, typically between 8-12%. This standardized approach ensures that all components have similar properties and minimizes issues related to dimensional changes caused by moisture fluctuations over time.

What Makes LVL Dimensionally Stable Compared to Traditional Wood?

Dimensional stability in LVL Construction Products comes from controlled moisture content and engineered layering that eliminates the natural movement found in solid timber. Traditional wood expands and contracts with humidity changes, causing warping, twisting, and structural problems that compromise building integrity over time.

Kiln-Dried Veneers Create a Moisture-Controlled Foundation

The manufacturing process begins with kiln-drying individual veneers to moisture content levels between 8-12%, significantly lower than the 19% or higher found in many traditional timber products. This precise moisture control removes the main cause of dimensional instability before the veneers are bonded together. Each thin layer undergoes thorough drying in industrial kilns, ensuring uniform moisture distribution throughout the material.

The controlled drying process achieves what natural seasoning cannot—complete moisture balance across every layer. Traditional timber often contains moisture gradients, where the outer surfaces dry faster than the core, creating internal stresses that result in warping months or years after installation. Kiln-dried veneers in LVL eliminate these gradients entirely.

Cross-Grain Layering Neutralizes Natural Wood Movement

The engineered layering system in LVL Construction Products for Stronger, More Consistent Structural Builds counters the natural tendency of wood to move across its grain. While all veneers run parallel in LVL (unlike plywood’s cross-lamination), the bonding process and thin veneer thickness create a composite that resists the expansion and contraction cycles typical of solid timber.

Individual veneers measure approximately 3mm thick, and when bonded under pressure with structural adhesives, they form a unified mass that behaves differently from a single piece of wood. The adhesive bonds lock the veneers together, preventing the independent movement that occurs in solid timber where growth rings can separate or twist as moisture levels fluctuate.

This warping resistance proves particularly valuable in applications like beams and headers spanning large openings. A solid timber beam might develop a bow or twist over several seasons as it adjusts to building humidity levels, potentially causing doors to stick or creating gaps in wall connections. LVL maintains its straight profile regardless of minor environmental changes.

How LVL Is Lightweight Yet Effective for Construction

LVL has an excellent high strength-to-weight ratio that makes it much lighter than steel and concrete while still being able to support similar loads. A typical LVL beam weighs about one-fifth of a steel beam and one-eighth of a concrete beam with the same strength. This significant reduction in weight changes how construction teams approach building structures without compromising on the performance standards needed for modern projects.

Weight Comparisons Across Structural Materials

The density of LVL usually falls between 500-650 kg/m³, which gives it a big advantage over traditional building materials:

- Steel beams: 7,850 kg/m³ density (about 12-15 times heavier than LVL)

- Reinforced concrete: 2,400 kg/m³ density (around 4 times heavier than LVL)

- Traditional solid timber: 400-700 kg/m³ (similar weight but weaker)

A 6-meter LVL beam measuring 300mm x 75mm weighs about 70 kilograms, while a steel I-beam with the same load capacity weighs around 350 kilograms. This five-fold difference in weight affects every stage of construction from transportation to installation.

On-Site Handling Benefits

Lightweight construction materials like LVL make daily tasks easier on construction sites. Two workers can safely lift and move most standard LVL beams without any machinery, while steel or concrete beams need cranes, hoists, or special lifting tools even for short distances.

The reduced weight puts less strain on construction workers, resulting in:

- Quicker positioning and adjusting during installation

- Lower chance of workplace injuries from manual lifting

- Less reliance on heavy machines for small home projects

- More flexibility in cramped or hard-to-reach areas

Sites with limited space for large equipment especially benefit from LVL’s manageable weight. Installing beams on the second floor, renovating occupied buildings, and working in remote locations with difficult access become much easier when structural parts can be carried instead of lifted by cranes.

Transportation Efficiency Advantages

Logistics costs go down significantly when using LVL instead of heavier options.

How Does LVL Contribute to Sustainable Building Practices?

LVL represents a significant advancement in sustainability in construction by utilizing renewable materials and maintaining a low carbon footprint throughout its lifecycle. The manufacturing process transforms fast-growing plantation timber into high-performance structural components, addressing environmental concerns while meeting modern building demands.

Reducing Deforestation Through Plantation-Grown Resources

LVL production relies on smaller diameter logs from managed plantation forests rather than old-growth timber. These plantations specifically cultivate fast-growing species like radiata pine, which reach harvestable maturity in 25-30 years compared to centuries for native hardwoods. Plantation forestry operates on rotation cycles, ensuring continuous replanting and sustainable yield without depleting natural forest ecosystems.

The smaller log requirement means trees unsuitable for traditional solid timber processing become valuable resources. Logs as small as 200-300 mm in diameter work effectively for veneer production, maximizing forest productivity per hectare. This efficient utilization reduces pressure on native forests while supporting regional plantation economies.

Managed plantations also sequester carbon dioxide throughout their growth cycle. Each cubic meter of LVL stores approximately 0.9 tonnes of CO₂, effectively locking atmospheric carbon within building structures for decades. This carbon storage capacity positions LVL as a climate-positive building material when sourced from certified sustainable forests. You may like to visit https://jeffclickhomes.com/scaffold-mesh-vs-scaffolding-mesh-are-they-the-same-and-which-offers-better-protection/ to get more about Scaffold Mesh vs Scaffolding Mesh: Are They the Same and Which Offers Better Protection?

Minimizing Production Waste

The LVL manufacturing process generates remarkably little waste compared to traditional timber milling. Rotary peeling technology removes thin, continuous veneer sheets from logs with precision, achieving utilization rates exceeding 85%. Traditional sawmilling typically wastes 40-50% of each log through sawdust, offcuts, and unusable sections containing defects.

Manufacturing facilities implement closed-loop systems where unavoidable waste becomes valuable byproducts:

- Veneer trimmings get processed into wood chips for particleboard or medium-density fiberboard production

- Adhesive residues undergo controlled combustion to generate facility heating and power

- Sawdust and bark supply biomass energy systems or agricultural mulch applications

- Defective veneers become raw material for composite wood products

This comprehensive waste management approach means virtually nothing from the LVL production process goes to waste.

What Are the Common Applications of LVL in Structural Projects?

LVL applications are used in almost every load-bearing element in modern construction, including horizontal beams and vertical supports. Its outstanding strength-to-weight ratio and consistent dimensions make it ideal for both residential and commercial projects where structural integrity is crucial.

Horizontal Load-Bearing Elements

Beams and lintels are the most common uses of LVL as beams and joists in construction. LVL beams bear the weight of roofs, upper floors, and create open spaces by spanning distances that would require multiple traditional timber supports. Window and door lintels made from LVL prevent sagging and deflection often seen with solid timber, preserving architectural lines while supporting masonry or cladding above openings.

Floor joists made from LVL provide better performance in residential and commercial flooring systems. The material’s consistent strength eliminates the bounce and vibration problems associated with traditional timber joists, especially in longer spans. Builders value how LVL floor joists maintain their shape during installation, ensuring even floors without the need for adjustments.

Rafters constructed from LVL handle snow loads and wind forces more effectively than regular timber. The uniform properties allow engineers to specify smaller member sizes while maintaining safety margins, creating more usable attic space and reducing overall building weight.

Wall Framing Components

Wall studs and plates made from LVL offer exceptional straightness for both load-bearing and non-load-bearing walls. The material’s resistance to warping ensures walls remain straight and true, making it easier to install cladding, drywall, and interior finishes. High-rise timber construction especially benefits from LVL wall framing, where consistent load transfer through multiple stories becomes critical.

Portal frames use LVL’s strength to create wide openings in commercial and industrial buildings. These frames eliminate the need for intermediate supports, providing flexible interior spaces that can be reconfigured without structural changes. The material’s predictable performance allows engineers to calculate exact load paths and deflection limits.

Trusses and Framing Components

LVL plays crucial roles in truss assemblies where reliability directly affects structural safety. As chord members, LVL forms the

How Does Availability in Various Sizes Benefit Construction Designs?

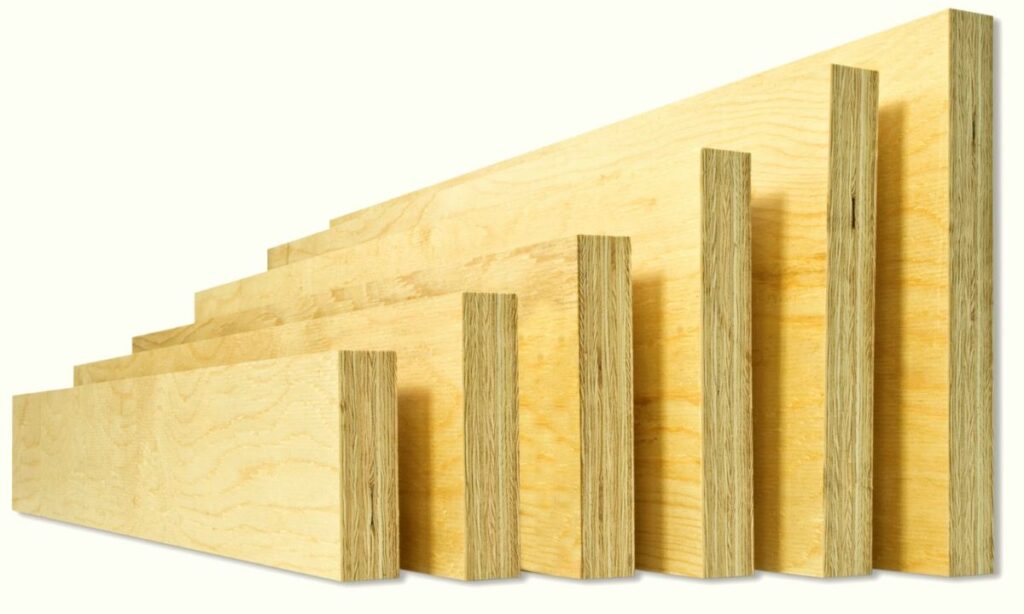

Standard beam dimensions provide builders with immediate solutions for most structural requirements without custom manufacturing delays. LVL beams come in depths ranging from 90 mm to 300 mm and widths from 45 mm to 75 mm, creating a comprehensive selection matrix that addresses different load-bearing scenarios. A 90 mm deep beam suits light residential applications like window lintels, while 300 mm depths handle substantial commercial loads across extended spans.

The width options allow engineers to fine-tune structural capacity by pairing appropriate depths with matching widths. A 45 mm width paired with a 240 mm depth creates a different load profile than a 75 mm width at the same depth, giving designers precise control over strength-to-weight ratios. This sizing flexibility eliminates the need to over-engineer structures with unnecessarily heavy members.

Matching Standard Sizes to Specific Structural Needs

Residential floor systems typically utilize 240 mm to 300 mm deep LVL beams with 45 mm widths for main support beams spanning 4 to 6 meters. These dimensions balance material costs with adequate load capacity for typical residential dead and live loads. Roof applications often require 170 mm to 240 mm depths depending on roof pitch, snow load requirements, and span distances.

Wall framing applications benefit from narrower 45 mm width beams at various depths, allowing them to fit within standard wall cavities while providing superior vertical load support compared to traditional timber studs. The 90 mm to 150 mm depth range works particularly well for load-bearing walls in multi-story construction where vertical compression strength matters more than horizontal span capacity.

Commercial projects demand the upper end of standard dimensions. A 300 mm deep beam with 75 mm width can replace steel I-beams in many applications, supporting concentrated loads at column points or carrying distributed loads across open-plan office spaces. These larger standard beam dimensions arrive ready to install without the lead times associated with custom steel fabrication.

Custom Wide Panels for Architectural Innovation

Custom sizing LVL beams extend beyond standard dimensions to accommodate unique architectural visions. Wide panels manufactured up to 1200 mm width open possibilities for curved walls, barrel roofs, and other creative designs that challenge conventional straight-line construction methods.

What Enhances the Durability of LVL Over Time?

The durability of LVL wood products comes from their engineered design and effective protective treatments that guard against environmental damage. When properly cared for with suitable moisture barriers and preservatives, LVL can retain its strength for many years, making it a trustworthy long-term building option.

The Importance of Moisture Protection

Moisture is the main enemy of engineered wood’s lifespan. LVL needs protective measures to stop water from seeping in and weakening the glue holding the veneer layers together. By sealing exposed edges and surfaces, we create a barrier that prevents moisture from being absorbed, especially at cut ends where the layered structure becomes susceptible to water intrusion.

Moisture protection treatments include several application methods:

- Penetrating sealers that soak into the wood fibres to repel water from within

- Surface coatings such as polyurethane or epoxy that form protective films

- Chemical preservatives that prevent fungal growth and decay in high-humidity environments

- Paint systems designed specifically for engineered wood products

The timing of treatment application matters significantly. Applying sealers immediately after cutting prevents moisture entry during the critical period before installation. Job site conditions often expose materials to rain or humidity, making pre-treatment essential for maintaining the lifespan of engineered wood components.

Understanding Service Life Expectations

Under ideal conditions, LVL is expected to last up to 50 years in dry indoor applications. This lifespan matches or exceeds that of traditional timber while offering greater uniformity throughout its lifetime. The absence of natural flaws like knots means LVL doesn’t develop weak spots that usually lead to early failure in solid lumber.

The 50-year benchmark assumes several maintenance conditions:

- Controlled indoor environment with relative humidity below 20%

- Protection from direct water contact through proper building envelope design

- Regular inspection of protective coatings and reapplication when needed

- Adequate ventilation preventing condensation buildup around structural members

Buildings in temperate climates with effective weatherproofing often see LVL components lasting beyond the 50-year mark.

How Do LVL Products Improve Efficiency on Construction Sites?

LVL Construction Products for Stronger, More Consistent Structural Builds deliver measurable time savings through their standardized dimensions and predictable characteristics. Construction efficiency with LVL begins the moment materials arrive on site, as builders can trust that every piece matches specified measurements without the dimensional variations common in traditional timber.

Standardized Dimensions Eliminate Guesswork

Traditional timber requires constant measurement and adjustment due to natural variations in size and shape. A nominal 2×10 piece of solid lumber might measure anywhere from 38mm to 42mm in actual width, forcing carpenters to check each piece individually. LVL beams arrive with precise, consistent dimensions that match engineering specifications exactly. A 45mm wide LVL beam measures 45mm throughout its entire length, eliminating the need for repeated verification.

This precision translates directly into reduced cutting time. Builders can measure once and cut multiple pieces with confidence, knowing each LVL component will fit perfectly. The time saved per cut might seem minimal, but across hundreds of structural elements in a typical project, these seconds accumulate into hours of saved labor.

Reduced Waste Building Material Consistency

Material waste represents both environmental and financial costs on construction sites. Traditional timber’s natural defects—knots, splits, warping, and dimensional inconsistencies—often result in rejected pieces or excessive trimming. Studies show conventional lumber projects typically generate 10-15% waste from defective or unsuitable materials.

LVL construction products dramatically reduce this waste stream:

- No rejected pieces due to knots or splits that compromise structural integrity

- Minimal trimming required since edges are manufactured straight and true

- Accurate material ordering based on reliable dimensions prevents over-purchasing

- Offcuts remain usable for smaller structural applications due to consistent quality

The engineered nature of LVL means every linear meter purchased delivers structural value. Builders can calculate exact quantities needed without adding excessive safety margins to account for unusable pieces. This precision in material planning reduces both waste disposal costs and the environmental impact of construction projects.

Predictable Performance Streamlines Assembly

Construction efficiency with LVL extends beyond cutting and measuring into the assembly phase. Traditional timber’s variable moisture content and grain